金属3Dプリンター

造形対応金属

対応金属の種類

日本積層造形株式会社 / JAMPT(ジャンプ)は、金属3Dプリンティング技術(金属積層造形技術)による総合サービスを提供しています。

JAMPTは電子ビーム方式(EB-PBF)およびレーザー方式(L-PBF)の金属3Dプリンターを複数台保有しており、様々な金属の積層造形に対応することが可能です。また、実績のない金属やマルチマテリアルの造形についても積極的にトライアルを実施しており、材料開発の段階からご相談に応じています。

電子ビーム方式 金属3Dプリンター(使用粉末粒径:45~105μm)

純チタン (Ti Grade-2)

| 元素 | Ti | C | Fe | O | N | H |

|---|---|---|---|---|---|---|

| 参考成分値 (%) | Balance | 0 – 0.08 | 0 – 0.3 | 0 – 0.25 | 0 – 0.03 | 0 – 0.015 |

チタン合金 (Ti-6Al-4V)

| 元素 | Ti | Al | V | Fe | C | O | N | H | Y |

|---|---|---|---|---|---|---|---|---|---|

| 参考成分値 (%) | Balance | 5.5 – 6.5 | 3.5 – 4.5 | 0 – 0.25 | 0 – 0.08 | 0 – 0.13 | 0 – 0.05 | 0 – 0.012 | 0 – 0.005 |

コバルト基合金(CoCrMo)

| 元素 | Co | Cr | Mo | Ni | Fe | C | Si | Mn | W | P | S | N | Al | Ti | B |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 参考成分値 (%) | Balance | 27.0 – 30.0 | 5.0 – 7.0 | 0 – 0.5 | 0 – 0.75 | 0 – 0.35 | 0 – 1.0 | 0 – 1.0 | 0 – 0.20 | 0 – 0.020 | 0 – 0.010 | 0 – 0.25 | 0 – 0.10 | 0 – 0.10 | 0 – 0.01 |

純銅(タフピッチ銅)

| 元素 | Cu |

|---|---|

| 参考成分値 (%) | >99.90 |

その他

ステライト、タングステンカーバイド、インコネル718、SUS316L

レーザー方式 金属3Dプリンター(使用粉末粒径:15~45μm)

ステンレス鋼(SUS316L)

| 元素 | Fe | Cr | Ni | Mo | Mn | Si | P | C | S |

|---|---|---|---|---|---|---|---|---|---|

| 参考成分値 (%) | Balance | 16.5 – 18.5 | 10.0 – 13.0 | 2.0 – 2.5 | 0 – 2.0 | 0 – 1.0 | 0 – 0.045 | 0 – 0.030 | 0 – 0.030 |

マルエージング鋼

| 元素 | Fe | C | Si | Mn | P | S | Cr | Mo | Ni | Ti | Co |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 参考成分値 (%) | Balance | 0 – 0.03 | 0 – 0.10 | 0 – 0.15 | 0 – 0.010 | 0 – 0.010 | 0 – 0.25 | 4.50- 5.2 | 17.0-19.0 | 0.8-1.2 | 8.50-10.0 |

ニッケル合金(インコネル625)

| 元素 | Ni | Cr | Nb+Ta | Mo | Fe | Ti | Al | Co | C | Mn | Si | P | S |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 参考成分値 (%) | Balance | 20.0 – 23.0 | 3.15 – 4.15 | 8.0 – 10.0 | 0.0 – 5.0 | 0.00 – 0.40 | 0.00 – 0.40 | 0.0 – 1.0 | 0.0 – 0.1 | 0.00 – 0.50 | 0.00 – 0.50 | 0.000 – 0.015 | 0.000 – 0.015 |

アルミ合金(AlSi10Mg)

| 元素 | Al | Si | Mg | Fe | Mn | Cu | Zn | Ti |

|---|---|---|---|---|---|---|---|---|

| 参考成分値 (%) | Balance | 9.0 – 11.0 | 0.2 – 0.45 | 0 – 0.55 | 0 – 0.45 | 0 – 0.05 | 0 – 0.10 | 0 – 0.15 |

アルミ合金(ANP-H4)

| 元素 | Al | Si | Mg | Mn | Fe |

|---|---|---|---|---|---|

| 参考成分値 (%) | Balance | 7 | 0.7 | 1.5 | 0-0.3 |

アルミ合金(Al-Mg-Sc)

| 元素 | Al | Si | Mg | Sc | Zr | Mn | Si | Fe | Ti |

|---|---|---|---|---|---|---|---|---|---|

| 参考成分値 (%) | Balance | 0 – 0.2 | 4.5 – 4.9 | 0.68 – 0.78 | 0.2 – 0.4 | 0.2 – 0.7 | 0 – 0.2 | 0 – 0.2 | 0 – 0.15 |

その他

SKD61、CuCr合金、コバルト基合金

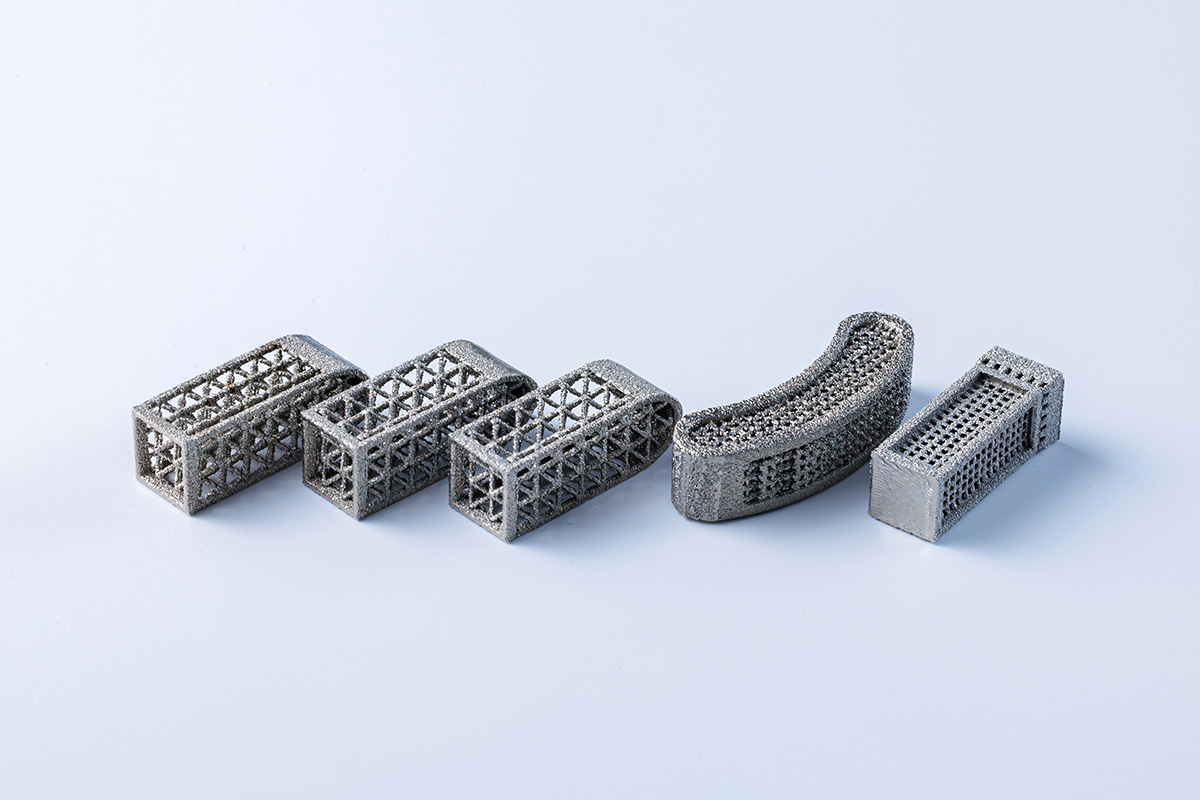

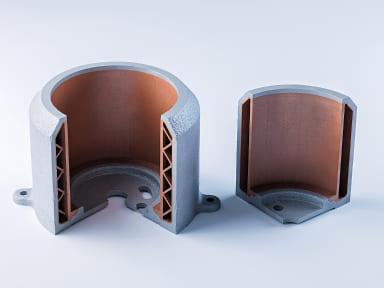

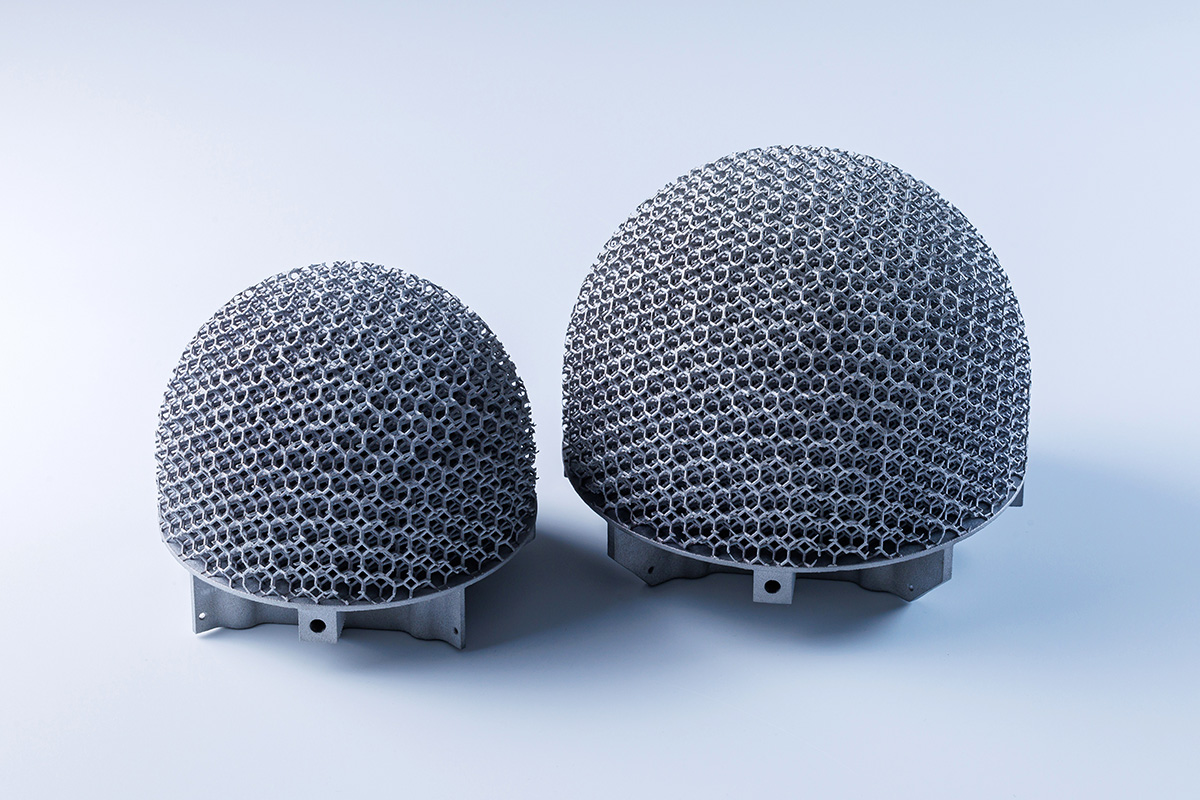

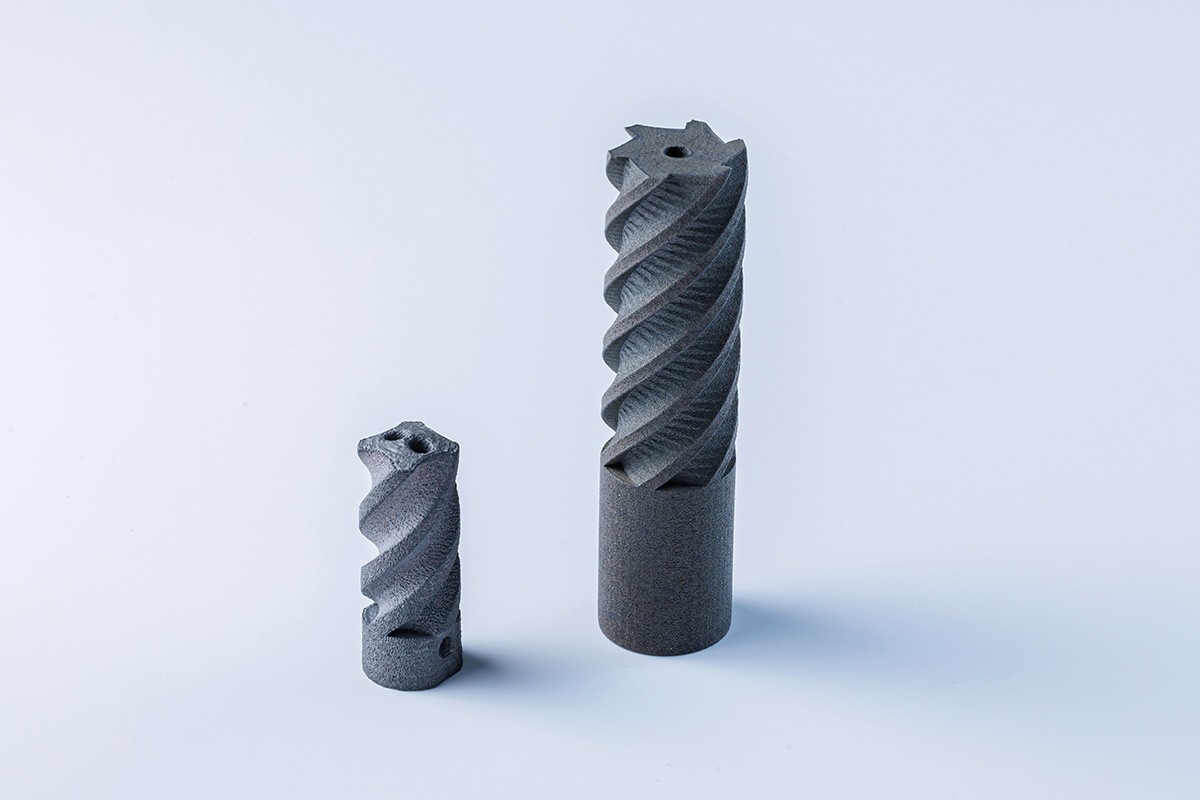

金属3Dプリンター造形物

SUS+銅合金造形品

アルミ合金:SLIM衝撃吸収体

タングステンカーバイド:超硬材造形ドリル