純銅の造形

金属3Dプリンターで純銅を造形

純銅について

当社ではタフピッチ銅と同等品質の材料粉末を用い、金属3Dプリンターで造形しています。

金属3Dプリンターについて

従来の切削・鋳造と異なり、金型を用いずに材料の金属粉末から直接製品の形状を造形します。

他の技術との違いについて

現在金属3Dプリンターで主流となっているレーザー方式(L-PBF)では困難/不可能な純銅での造形を短期間で実現します。

金属3Dプリンターによる銅の造形につきましては、こちらの当社コラム記事も参照下さい。

| 金属3Dプリンター方式 | 造形サイズ | 造形速度 | 複雑構造 | コスト |

|---|---|---|---|---|

| 当社の 電子ビーム方式 |

〇 | 〇 | 〇 (焼結体の除去)※1 |

〇 |

| 他社の 緑色レーザーAM技術 |

△ | △ | 〇 | △ |

| 他社の 通常レーザー方式(赤色レーザー) |

× 現状不可能※2 |

|||

※1 造形後に焼結体の除去が必要なため、複雑な中空構造は難しい場合があります。

※2 高価な高出力レーザーによる造形は可能だが、イニシャルコストが課題となります。

お客様の設計形状で安定的な造形品質を確立します。

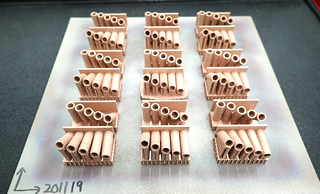

パイプ肉厚 ≧ 0.8mm(現状の実績)

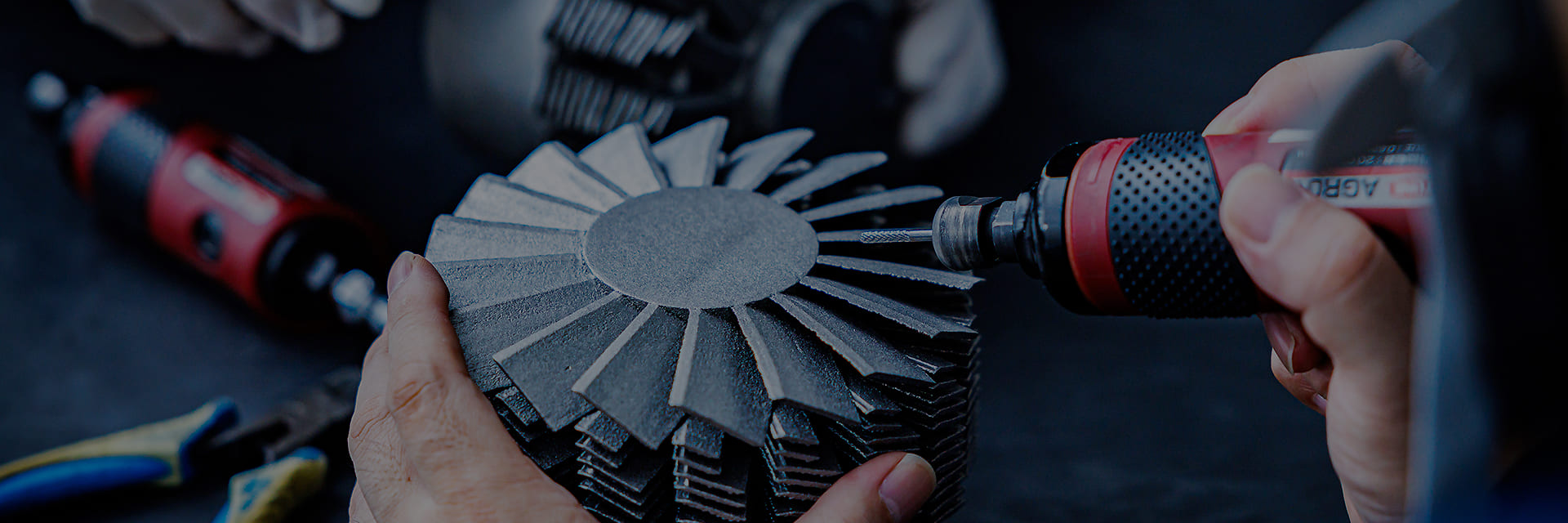

活用事例:高周波焼入れコイル

金属3Dプリンターに設定入力する造形条件の最適化に取り組むことで、お客様の設計形状で安定的な造形品質を確立します。

更に、金属3Dプリンターならではの形状の最適化・再設計のお手伝いをさせて頂きます。

試作・開発のご相談を頂いています。

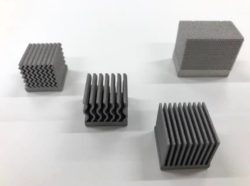

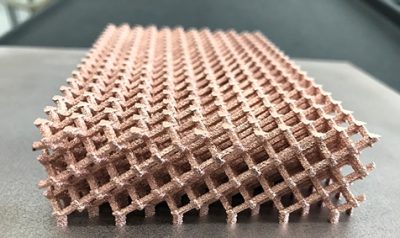

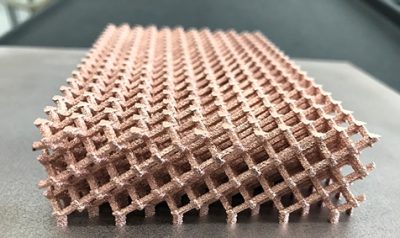

ラティス(格子)線径 @ 1mm

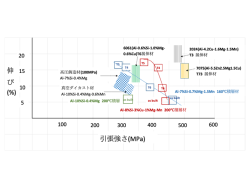

金属3Dプリンターによる加工プロセスでも、従来材料と同等の物性(導電率・熱伝導率)を確認しています。

放熱材やコイルに関する試作・開発のご相談を様々な業界分野より頂いています。

【造形に用いる電子ビーム方式金属3Dプリンター】

1. 電動化に貢献する銅

CO2排出削減のため、電動化の技術開発が急速に進められる中、モーターをはじめ導電率の高い純銅を金属3Dプリンターでも活用する取り組みに注目が集まっています。海外の大手金属3Dプリンター装置メーカーでは、これまで汎用装置では造形できなかった純銅材を、緑色や青色や高強度レーザーの採用によって造形できるようにする研究開発がすすめられており、また材料メーカーでも、通常のレーザー方式金属3Dプリンターに搭載されているファイバーレーザーでも造形可能な銅合金材が開発されています。

2. 電子ビーム x 純銅

通常、銅分99.9%以上の無酸素銅/タフピッチ銅相当の純銅は、反射率の高さと熱伝導性から、レーザー方式では粉末材料(粉末床, Powder Bed)を安定的に溶融することができず、造形ができませんでした。

JAMPTでは、国内でも数少ない電子ビームを熱源とする金属3Dプリンターを用いて、この技術課題を解決し、また造形時の入熱・溶融条件を最適化することで、安定的な造形を実現することができました。

3. 加工の難しい材料

純銅はその高い導電率や熱伝導率から、コイルや熱交換器に多く活用されてきましたが、展性・延性に富む材料であることから、精密な加工が難しく、また熱の拡散によって溶接加工も難しく、複雑な形状への成形が必要な場合は、ロウ付けなどの加工がなされてきました。

4. 熱応力と仮焼結

融点の低い材料である純銅の造形では、最適な入熱条件・溶融条件を決定することが非常に難しく、また電子ビーム方式金属3Dプリンターの特徴である予熱という過程において熱応力を除去することができますが、それでもなお、急速な溶融・凝固を行うプロセスでは、熱変形の生じやすい材料であることがわかりました。

また、前述の通り電子ビーム方式で行う予熱工程において造形物の周囲の粉末が仮焼結体を形成する為、造形完了後に仮焼結体除去の後加工が必要となりますが、複雑な中空構造や内部流路の造形を行う場合は、内部の仮焼結体の除去に技術的な課題があることがわかりました。

5. 活用への期待

現在JAMPTでは、自動車(EV・FCV)分野での基礎研究における試作から、高周波焼入れコイルの試作品・実用品、また高度な放熱性能を求められるヒートシンクへの活用に向けた試作など、電子ビーム方式金属3Dプリンターを用いた純銅の造形のご依頼を各方面から頂いております。

今後も純銅の造形によって、これまでに無い製品づくりへのお手伝いをさせて頂きたいと考えておりますので、お気軽にご相談ください。