金属3Dプリンターの方式

電子ビーム方式(EB-PBF)・レーザー方式(L-PBF)の違いについて

パウダーベッド方式の金属3Dプリンターには、電子ビーム方式(EB-PBF)とレーザー方式(L-PBF)が代表的ですが、それぞれ対応できる金属材料の種類や、造形物の品質(表面粗さや寸法精度等)に違いがあります。両方式の特徴を知ることにより、どちらの方式が目的とする製品の造形に適しているか判断することが可能となります。

レーザー方式ではレーザー光をレンズで集約して機械的に照射方向を制御します。一方、電子ビーム方式(EB-PBF)では電気的に照射方向を制御できるので溶融工程が早いのが特徴です。

電子ビーム方式(EB-PBF)とレーザー方式(L-PBF)の違い

| 熱源 | 電子ビーム方式 (EB-PBF) | レーザー方式 (L-PBF) | 相違点の ポイント |

|---|---|---|---|

| 出力 | 高い(3.5~6.0kW) | 低い(0.4〜0.6kW) | |

| 金属材料 | 高融点材の対応が可能 | 高融点材の対応は困難 (反射率の高い純銅等は難) | |

| 粉末粒径 | 45~105μm | <45μm | 粉末粒径45~105μm<45μm 出力の違いにより使用する粉末の粒径が異なる (現状、電子ビーム方式は粒径の大きい粉末を使用しています) |

| 積層厚 | 50~90μm | 20~50μm | 積層厚の違いは造形時間に影響 |

| チャンバー内 | 真空・予熱 | 不活性ガス置換 | 電子ビーム方式(EB-PBF)では真空・予熱工程が必要 レーザー方式(L-PBF)ではガス置換により酸化を防ぐ |

| 表面粗さ | Ra25 | Ra10 | 粉末粒径と積層厚は表面粗度に影響 |

| サポート (応力除去) | 簡素(予熱するため) | 必要(常温のため) | サポート材は除去作業(後工程)と原料粉末の歩留りに影響 |

- 電子ビーム方式(EB-PBF)はレーザー方式(L-PBF)に比べて出力が高いため、造形スピードが速くなる。

- 電子ビーム方式(EB-PBF)では、帯電防止処理として仮焼結を行うため、造形後の残留応力の発生が少なく、内部応力による歪みや亀裂も抑制され、サポート材も少なくて済む。

- レーザー方式では粒径の小さい粉末を使用するため、製品の表面粗度は優れており、比較的細かい構造物の造形に適している。

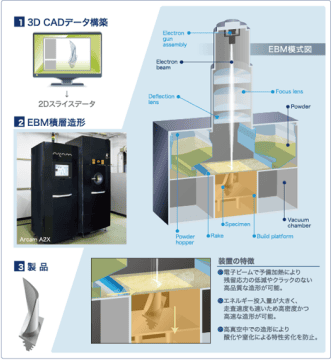

電子ビーム装置の特徴

- 電子ビームによる予備加熱で残留応力の低減やクラックのない高品質な造形が可能です。

- エネルギー投入量が大きく、走査速度も速いため高密度かつ高速な造形が可能です。

- 高真空中での造形により、酸化や窒化による特性劣化を防止できます。

電子ビーム方式(EB-PBF)による造形のメリット

電子ビーム方式(EB-PBF)で造形することにより、造形時間を大幅に短縮することができ、レーザー方式(L-PBF)と比べて大きなコスト削減効果+短納期が期待できます。また、電子ビーム方式(EB-PBF)は仮焼結のための予熱効果により高温環境下で造形されるため、応力除去などの熱処理も基本的に不要です。

例:SUS316L材造形 20 x 20 x 20mm

| 造形個数 | L-PBF 造形 時間(h) (Concept Laser M2) | EB-PBF 造形 時間(h) (Arcam A2X) | 造形時間 短縮効果 |

|---|---|---|---|

| 1 | 5 | 10 | +100% |

| 10 | 29 | 15 | -49% |

| 20 | 56 | 21 | -63% |

| 30 | 82 | 27 | -67% |

| 40 | 109 | 33 | -70% |

| 50 | 133 | 39 | -81% |

| 引張強度 (MPa) | 降伏応力 (MPa) | 伸び (%) |

|

|---|---|---|---|

| ASTM F3184規格 | 515 | 205 | 30 |

| JAMPT L-PBF 実績値 | 450-550 | 200-250 | 20-25 |

| JAMPT EB-PBF 実績値* | 460-480 | 224 | 28 |

*更に強度を出すための試験は継続中