サービス紹介

技術と知識で対応

日本積層造形株式会社 / JAMPT(ジャンプ)は金属3Dプリンター専門のサービスビューロとして、

試作から製品実用化、量産化までの一貫サービスを提供いたします。

これまで培ってきた高い技術と専門知識で、あらゆるニーズにお応えします。

このようなお悩み・ご要望に

対応しています

- 大きい造形物にも対応してほしい

- 補用部品として同じものを造形したいが図面がない

- 新規開発粉末で造形をしたい

- 真球度の高い粉末や造形性をよくするための敷性の良い粉末を探している

- 既存の部品を金属3Dを利用して軽量化を図りたいが、ベストな設計方法がわからない

- 単一材料ではなく目的に合わせて複数材料で造形はできないか

- 低コスト・軽量化を実現したい

JAMPTの機能と5つの強み

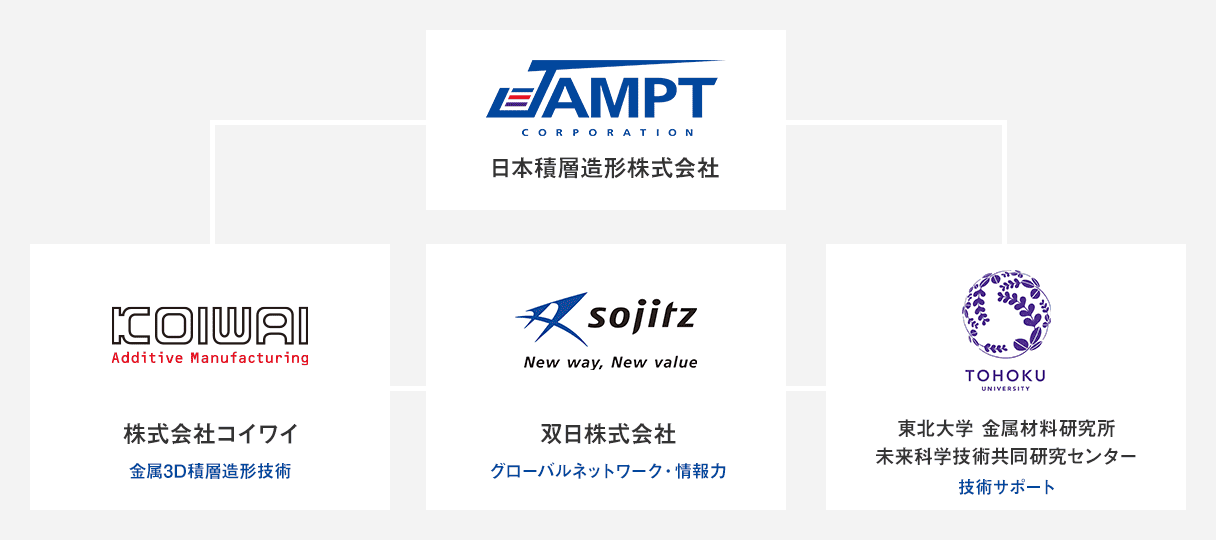

日本積層造形株式会社 / JAMPT(ジャンプ)は、金属3Dプリンターの分野において、日本で初めて粉末開発・製造から試作品造形・量産対応までワンストップのサービスを提供することが可能なサービスビューロ(SB)です。

国内SBの草分け的存在である株式会社コイワイの金属積層造形技術と東北大学・千葉晶彦特任教授(未来科学技術共同研究センター)の学術的裏付けを基とした技術サポート、双日株式会社のグローバルネットワークと情報力を大きな強みとして、金属3Dプリンターの分野で先進的な機能を発揮していきます。

JAMPTの機能

- 実用化に向けた一貫サービスの提供

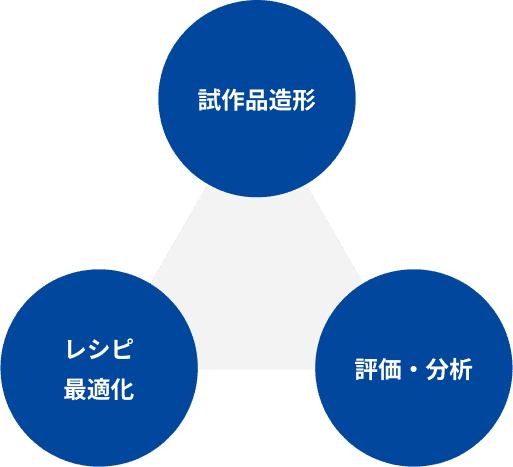

日本積層造形株式会社 / JAMPT(ジャンプ)は粉末開発・製造から試作品造形、評価・分析そして量産対応までワンストップのサービスを提供することが可能です。

加えて、造形後の評価・分析結果から、学術的裏付けに基づき造形レシピ(入熱等の設定条件)を最適化することができ、更なる造形品質の改善に取り組んでいます。

試作品造形 ⇒ 評価・分析 ⇒ レシピ最適化というプロセスを繰り返し重ねることで、最終的に金属3Dプリンターによる実用品・部品製造を目指す事ができます。

JAMPTの5つの強み

- 1大型レーザー・電子ビーム装置を

共に操る造形技術 日本積層造形株式会社 / JAMPT(ジャンプ)は、国内最大規模の金属3Dプリンター保有台数(7台)を誇り、お客様の多様なニーズにお応えします。電子ビーム方式(EB-PBF)とレーザー(L-PBF)の両方式の金属3Dプリンター、短時間で造形可能な4本レーザー搭載の最新鋭の装置までを揃えており、幅広い鋼種の対応や造形が可能です。

- 2100種類を超える豊富な

金属粉末造形実績 日本積層造形株式会社 / JAMPT(ジャンプ)は、創業から累計で100種類を超える金属粉末での造形実績があります。

短期間で最適な材料・造形レシピ(入熱等の設定条件)を策定し、造形時のレイアウト、サポート材に関する独自のノウハウも活用し製品造形に対応します。

また、豊富な装置ラインナップ及び熟練した技術スタッフにより、一般的な材料以外の特殊材料や、お客様が選定または新たに開発された材料での金属積層造形にも日々挑戦し、更なる造形ノウハウを蓄積しています。

- 3東北大学・金属材料研究所との

連携による材料開発支援 日本積層造形株式会社 / JAMPT(ジャンプ)では、東北大学および真壁技研と産学連携の材料開発支援を行っています。

ガスアトマイズ法等の高効率な粉末製造技術と、当社の3Dプリンター専用の高品質な粉末技術ならびに幅広い材料に対応できる造形技術を融合して、お客様の新たな材料開発ニーズに対し、粉末試作から造形・評価まで、ワンストップでサービスを提供いたします。

- 4ガス欠陥なく、真球度が高い

PREP粉末の製粉技術 PREP法は、プラズマにより溶融した電極棒先端の金属液滴が、高速回転で飛散することによって粉末化される製粉技術です。

大気圧条件で製粉され、金属液滴へのガスの巻き込みが無いため、内部ガス欠陥が無く、真球度が高く、サテライト付着が無い、クリーンな粉末として知られています。

日本積層造形株式会社 / JAMPT(ジャンプ)では、金属3Dプリンター向けに実用商業化開発を進めています。

- 5JIS Q9100/ISO52920認証取得で

安定した高い品質を確保 日本積層造形株式会社 / JAMPT(ジャンプ)では、ISO 9001要求事項に、航空・宇宙及び防衛分野の特有な要求事項を加えたJIS Q 9100の認証を取得しています。

更に、3Dプリンタの国際基準ISO/ASTM52920準拠の「製造サイト認証」を2024年1月に国内の専業サービスビューロとして初めて取得しました。これにより、試作造形のみならず量産品も含め、国際基準に準拠した、一貫して顧客要求品質を満足する3D造形工程の体制およびオペレーション能力が証明されました。

3大サービス

試作・受託造形サービス

- お客様の試作開発ステージにおいて、試作品を短納期で対応いたします。

- 100種類以上の粉末の対応実績をもとに、お客様オリジナルの材料での試作にも対応いたします。

- 実用品の多品種少量生産に対応いたします。

- 図面のない旧部品をリバースエンジニアリングによって小ロットから製作いたします。

製品開発(DfAM)支援サービス

- お客様の製品開発ステージにおいて、試作・評価のお手伝いをいたします。

- 量産コストの試算から、コスト低減に向けたパラメータ開発のお手伝いをいたします。

- 量産時の品質管理について、評価・アドバイスをさせていただきます。

- 金属3Dプリンターならではの設計(DfAM)により、さらなる形状・材料の最適化をご提案いたします。

- 協業先とのタイアップによりCFRP+金属積層品のハイブリッド製品の提案も可能です。

材料開発支援サービス

- お客様の金属3Dプリンター用材料開発において、小ロットでの製粉に対応いたします。

- お客様が開発中の金属3Dプリンター用材料粉末の試験造形・比較評価を請け負います。

- 数リッター程度の粉末があれば試験造形が可能です。

- お客様のオリジナル材料での造形、機械的特性の試験・評価に対応いたします。

- 当社で開発する金属3Dプリンター用の真球度が高く、ガス欠陥がなく、かつサテライト付着がない高品質な粉末(PREP粉末)を生産・販売いたします。